Our Products

Provang Heat Treatment Furnaces

We stand as prominent Manufacturers and Traders, specializing in Furnaces, Furnace Accessories, Ovens, Process Automation & Control Panels, Digital Temperature PID Controllers, Thermocouples / RTD's, and Industrial Heaters for the past two decades. Equipped with state-of-the-art facilities, we ensure the fulfillment of customers' stringent quality requirements. Our products are meticulously crafted under the supervision of highly skilled technocrats and seasoned professionals.

We possess the capability to design and manufacture materials tailored to the specific requirements of our customers. Our fully equipped facilities enable the manufacturing of a diverse range of materials. We guarantee the delivery of high-quality products and dedicate our utmost attention to meeting your demands and orders, aiming to become one of your trusted and reliable vendors and end users.

We are a proficient, professional, and innovative supplier specializing in industrial furnaces.

Custom Built Furnaces

Complete Range of Furnaces

Heat Treatment Furnaces

Efficient range of calibrated thermocouples and RTD's

▮ ▮ ▮ ▮ ▮

1. Bell Furnaces

Bell Furnaces are indispensable in industries requiring an enclosed atmosphere for methods or applications. Primarily sought after in specific plants, they excel in applications such as annealing steel strips, annealing steel wires, normalizing steel castings, and decarburizing stamps. Various applications of this furnace include:

Annealing of steel strips

Annealing of steel wires

Normalizing steel castings

Decarburizing of stamps

2. Chamber Furnaces

Chamber Furnaces cater to a spectrum of heat-treatment applications, including stress relieving, normalizing, hardening, and tempering.

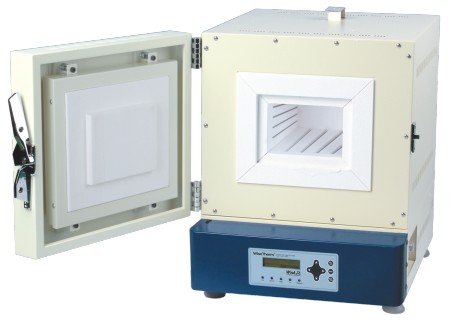

3. Muffle Furnaces

Provang offers a diverse selection of top-quality Muffle Furnaces, ranging from laboratory to portable, industrial, and benchtop furnaces. Our specialty lies in designing and manufacturing custom muffle furnaces.

4. Bottom Loading Furnaces

The single-zone, high-temperature Bottom Loading Furnace operates at temperatures up to 1880°C in air. Ideal for materials annealing and sintering, it utilizes molydisilicide heating elements and an energy-efficient insulation package.

5. Pit Type Furnaces

Pit Furnaces find applications in various heat treatment processes, commonly used for tempering automobile parts and annealing M.S. wire.

6. Controlled Atmosphere Furnaces

Controlled Atmosphere Furnaces support heat treatment in numerous atmospheres, including hydrogen, nitrogen, argon, ammonia, carbon dioxide, helium, and various other reducing and oxidizing atmospheres.

7. Normalizing Furnaces

Normalizing Furnaces apply heat treatment to ferrous materials, enhancing mechanical properties by refining the microstructure.

8. Annealing Furnaces

Annealing Furnaces are pivotal in altering material strength and hardness, relieving internal stresses, and improving mechanical and electrical properties.

9. Bogie Hearth Furnaces

Ideal for annealing and hardening larger parts, such as heavy cast parts or tool steel dies, Bogie Hearth Furnaces recommend radiation heating. Featuring electro-hydraulic lift doors and motorized bogies, they optimize process times.

10. Rotary Furnaces

Rotary Furnaces, with their refractory lined cylindrical vessel, front-mounted burner, and rear flue discharge, are designed for applications like copper, lead, or zinc smelting, and aluminum dross or scrap recycling.

Applications

Copper Lead or Zinc Smelting

Aluminium Dross or Scrap Recycling

Benefits

Conventional Process

Efficient and Economical furnace configuration

11. Hot Air Oven

Hot Air Ovens are meticulously crafted to meet practical requirements in laboratories, hospitals, and industries. Ideal for precise temperature applications, they find applications in various industries, including pharmaceuticals, chemicals, food, agriculture, and more.

12. Lab Oven - Electrical Heating Oven

Lab Ovens, essential for methods or applications requiring an enclosed atmosphere, are highly sought after in specific plants, providing efficient handling for larger batches.